A flow meter is a device used to measure the flow rate or quantity of a gas or liquid moving through a pipe. Flow measurement applications are very diverse and each situation has its own constraints and engineering requirements. Flow meters are referred to by many names, such as flow gauge, flow indicator, liquid meter, etc. depending on the particular industry; however the function, to measure flow, remains the same.

A flow meter is a device used to measure the flow rate or quantity of a gas or liquid moving through a pipe. Flow measurement applications are very diverse and each situation has its own constraints and engineering requirements. Flow meters are referred to by many names, such as flow gauge, flow indicator, liquid meter, etc. depending on the particular industry; however the function, to measure flow, remains the same.

Why do I need a precision flow meter? You might not! Precision flow meters are used to provide accurate monitoring and/or flow control. Some industrial applications require precise calculation of quantity, such as precision servo-valve development for the aerospace industry. On the other hand, an application to measure water flow to a vineyard may only require a measurement accuracy of 5% to 10%.

What are the various types of flow meters?

**Please click through the links offered below to delve deeper into each technology**

Positive Displacement (Also known as a Volumetric flow meter or PD flow meter).

All Max Machinery flow meters are Positive Displacement/Volumetric.

Positive displacement flow meters are unique as they are the only meter to directly measure the actual volume. All other types infer the flow rate by making some other type of measurement and equating it to the flow rate. With PD meters, the output signal is directly related to the volume passing through the meter. Includes bi-rotor types (gear, oval gear, helical gear), nutating disc, reciprocating piston, and oscillating or rotary piston.

Mass

The output signal is directly related to the mass passing through the meter.

Thermal and Coriolis flow meters fall into this category.

Velocity

The output signal is directly related to the velocity passing through the meter.

- Electromagnetic

- Ultrasonic

- Turbine, Propeller, and Paddle Wheel or Pelton Wheel

- Vortex Shedding and Sonar

- Target and Vane

- Variable Area and Rotameter

- Orifice Plate, Open Channel, Flow Nozzle, Laminar, Venturi, and Pitot Tube

What type of flow meter is best? There are no “universal” flow meters which are suitable for all applications. Selecting the proper technology for your application requires writing a flow specification which covers the use of the meter. There are usually trade-offs with each meter type, so knowing the critical specifications will be important. Things you must know:

- What Gas or Liquid will be measured?

- Minimum and maximum flow rates.

- What are the accuracy requirements?

- The fluid temperature and viscosity.

- Fluid compatibility with the materials of construction (See our materials compatibility guide)

- The maximum pressure at the location.

- What pressure drop is allowable?

- Will the meter be mounted in a hazardous location where explosive gases may be present?

- Is the fluid flow continuous or intermittent?

- What type of output signal or readout do you need?

You will use this list to eliminate the technologies that do not apply (ex. Turbines don’t work for viscous fluids, Coriolis meters don’t respond fast enough for injection flow). Then you will have an apples-to-apples comparison of the remaining technologies. Accurate meters are priced based on their capabilities. It is better to locate the type of meter which fits your application before trading features for cost savings. Closely evaluate your extreme conditions, such as low flow rates, high pressure or temperature or the need to measure over a wide operating range. If these conditions are important, do not be swayed by lower priced alternatives that would be applied outside of their capabilities.

If you found this article useful, please share it with your network, via the social media links at the top. Thanks.

Read More about Max Meters

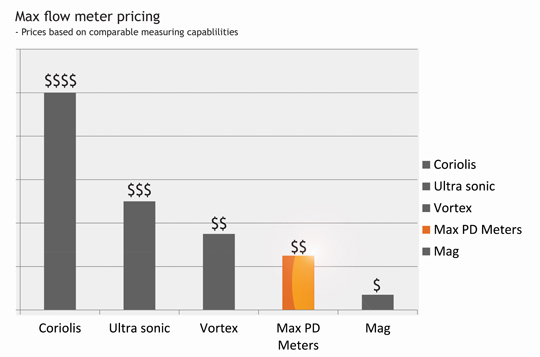

What is the price of a Max Machinery flow meter? The price of a Max positive displacement flow meter will vary based on the size of pipe or line being measured. The various output options and other flow specification considerations are unique to each order. The graph below shows the general pricing.

Every Max meter comes with a NIST traceable calibration covering its entire 100:1 to 2000:1 range. Verifiable accuracies to better than 0.3% of reading. For more accurate pricing based on your specific needs please request a quote

Why would I choose a Max flow meter for my application? The largest concentration of meter manufacturers falls under the technologies of P.D., turbine, Coriolis mass flow and thermal mass flow. There are Pros and Cons for each technology, but the major advantages you’ll enjoy with Max are:

- A wider operating range than any other technology, including other P.D. meters

- The ability to measure low flow rates down to 0.005 cc/min, which is comparable to thermal mass but much better than turbine, Coriolis or other P.D. meters

- Accurately reports the flow of intermittent injection streams, which Coriolis, turbines and thermal mass cannot.

Installation and Use: We provide free technical consultation for the lifetime of your Max flow meter. We are committed to providing our customers with the information that they need for a successful and easy installation.

MAX Lifespan: We manufacture our flow meters to last a long time. It’s quite possible the Max flow meter you are using has been in place and properly functioning for 15-20 or more years. This means that when it comes time to replace your system the exact model you have has probably been updated. So, not only will you be acquiring another reliable flow sensor you will be gaining all of the advances in metallurgy, coatings advancements and the latest improvements in electronics technology. When you need another meter, ask about the improvements that have gone into upgrading your old design to the latest model number.

What are some of the most common applications of MAX flow meters? Taking advantage of the inherent strengths of P.D. meters, Max meters are usually specified for intermittent flow measurement, such as Natural Gas odorant injection, or additive injection of corrosion inhibitors into pipelines. Our low flow rate capabilities are the key for fuel measurement on everything from large diesel engines to single fuel injectors on GDI (gasoline direct injection) engines. Because the Max meters are not sensitive to changes in fluid viscosity, high viscosity applications like, asphalt, tar, hot melt adhesives and silicones are accurately measured without a need to compensate for the changing fluid properties. A wide operating range of 200 to 1 up to 2000 to 1 gives the user the ability to replace several flow meters with a single sensor. If you would like a quote for a demanding project, please let us know.