Positive Displacement (PD) Flow meters are volumetric flow measurement instruments that measure flow by passing a precise volume of fluid with each revolution. PD flow meters are precision instruments whose internal moving components are hydraulically locked in tandem with the volume of fluid moving through the flow meter. The result is that the meter can measure intermittent flows, very low flow rates, and liquids of almost any viscosity. The PD meter instantly moves when there is fluid motion, and instantly stops when the fluid motion stops.

This type of measurement is not affected by the liquid’s viscosity, density or the turbulence in the pipe. All incompressible fluids will occupy the same volume and there is no need to correct the meter’s output to compensate for these factors.

Each measured volume of fluid is uniquely separated from the next by a frictionless liquid seal. The effectiveness of this seal is a function of the precision to which the meter is manufactured and the ease with which the flow meter rotates. The close clearances of the internal measurement components require the PD flow meter be used with relatively clean fluids. The meter’s materials of construction dictate the list of process liquids which will be compatible. Their high precision has allowed PD flow meters to be almost universally accepted for billing and transfer standard applications, such as gasoline and fuel oil dispensing, natural gas or water measurement.

There are many types of positive displacement flow meters, including; reciprocating piston, oscillating or rotary piston, bi-rotor types (spur gear, oval gear, helical gear, rotary vane), and nutating disc (wobble plate).

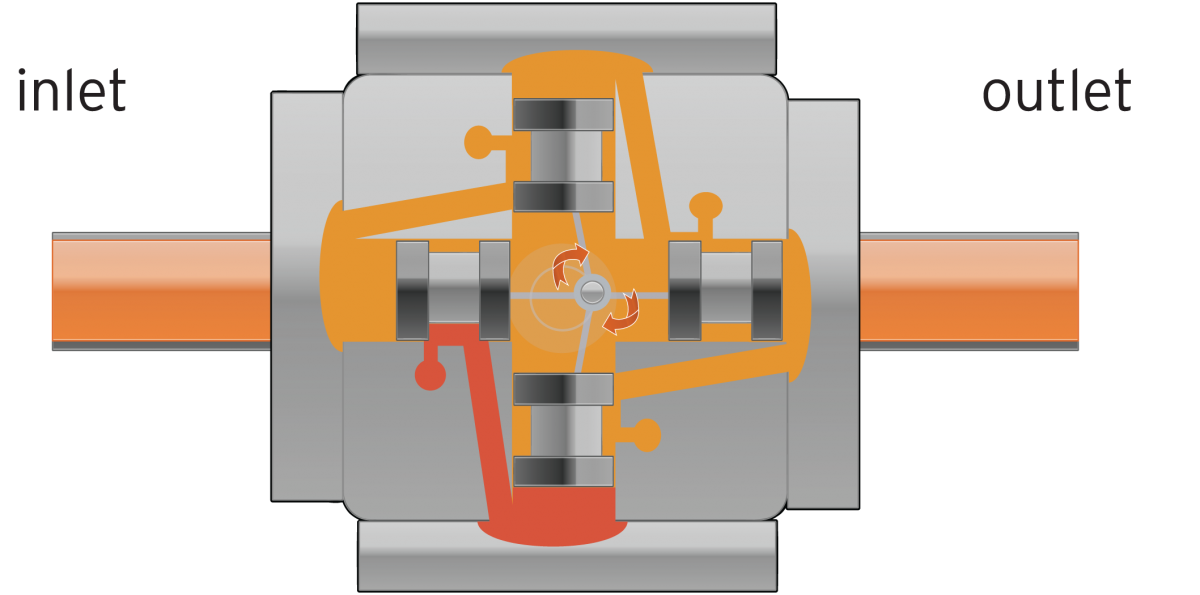

Piston flow meters

Piston flow meters are of single and multiple-piston types. The pistons displace fluid in the same way that a syringe operates. Each piston displacement captures the same amount of fluid.

Watch video on our Piston Meter Family page.

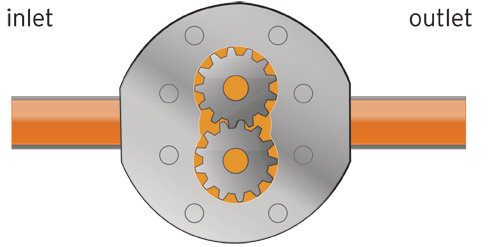

Gear flow meters

Gear flow meters use two round gears that are mounted in overlapping compartments. The measured fluid is trapped in the voids of the gear teeth and transported from the inlet port to the outlet port as the fluid flow causes the gears to rotate.

Watch video on our Gear Meter Family page.

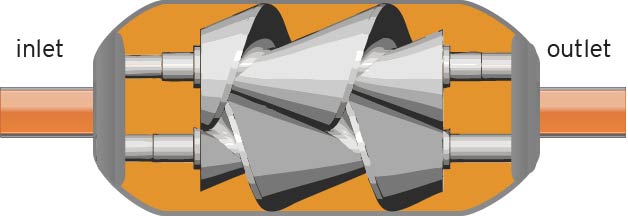

Helical flow meters

Helical [Gear] Flow Meters use two screw-shaped rotors to chop the fluid stream into fixed displacement volumes. The rotors' orientation is in-line with the fluid flow path. These meters rotate with a very low pressure drop, and can turn at high rpm’s making them accurate over wide flow ranges and compatible with very high viscosity fluid applications.

Watch video on our Helical Meter Family page.

Other PD Flow Meters

Oval-gear meters have two rotating, oval-shaped gears with synchronized, close fitting teeth. A fixed quantity of liquid passes through the meter for each revolution.

Rotary vane meters consist of equally divided, rotating impellers, in two or more compartments, inside the meter's housings. The impellers are in continuous contact with the casing. A fixed volume of liquid is swept to the meter's outlet from each compartment as the impeller rotates.

Nutating disk meters have a moveable disk mounted on a concentric sphere located in spherical side-walled chambers. The pressure of the liquid passing through the measuring chamber causes the disk to rock (wobble) in a circulating path without rotating on its axis. The disk/sphere is the only moving part in the measuring chamber.

Additional Considerations

There are a variety of methods used to provide output signals and readouts. The simplest methods only count each full revolution, while more sophisticated instruments provide high resolution signals with up to 4000 measurements per revolution.

PD meters are not sensitive to changes in pressure, temperature or viscosity. The meter's displacement and K-Factor do not need to be compensated for these changes.

Accuracy and Turndown ratio varies widely by type and manufacturer, but many meters fall in the range of 0.1% to 1.0% of reading, with Turndowns ranging from 10:1 to 200:1 or more. Due to their high accuracy, PD meters are the most widely used meters for custody transfer applications.

Prices of positive displacement meters can vary widely. A simple water meter for your home may cost less than $100, while prices for larger meters can run up to several thousand dollars.

-If you would like to know more about Positive Displacement Meters, please use our contact form to send your questions.