Turbine Flow Meter

There are many different manufacturing designs of turbine flow meters, but in general they are all based on the same simple principle. Fluid moves through a pipe and acts on vanes, causing a turbine rotor to spin. The rotor spins as the liquid passes through the blades. The turbine blade motion is sensed by a magnetic pick-up and an electrical pulse is generated. The number of electrical pulses counted for a given period of time is directly proportional to flow volume. To achieve a repeatable result, the liquid flow must be fully developed and stable across the cross section of the pipe. To achieve this stable profile, a few diameters of straight pipe on the inlet and the outlet are required to achieve accurate measurements. They can be used for clean liquids with viscosities up to 50 centistokes. The turndown ratio can be as high as 100:1 if the turbine meter is calibrated for a single fluid and used at constant conditions. The majority of turbine meters have an accuracy of 0.5% to 1.5% of reading.

Paddle Wheel Flow Meter

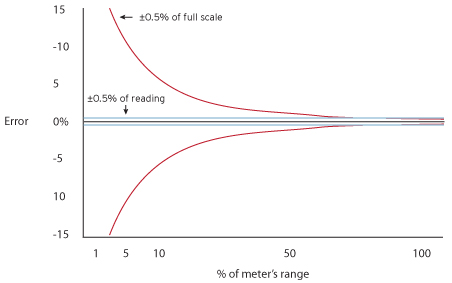

The paddle wheel flow meter is a cost effective device typically used for water or water like fluids. These meters, like the turbine meter, require a few pipe diameters of straight pipe on the inlet and on the outlet. Chemical compatibility should be verified when not using water. The rotor of the paddlewheel sensor is perpendicular to the flow and contacts only a limited cross section of the flow. Prices typically are in the range of $100 to $600. Accuracy is typically 1 to 3% of full scale. An accuracy measured against the full range of the device will double at 50% of full scale and triple at 33% of full scale. Caution should be used when measuring with a device that states a “full scale accuracy” as opposed to an “of reading accuracy” (see example below).

-Presented by Max Machinery, Inc. the Positive Displacement Meter Experts