As the operating pressure of hydraulic systems increase, the component test stands need to follow suit. Testing cylinders, valves or pumps at less than their rated pressure is not a true test of their performance, so life cycle testing is usually performed at elevated pressures and flow rates as part of an accelerated life test. To monitor performance throughout these tests requires a hydraulic flow meter with the rangeability and pressure specification needed to cover the testing extremes. A reliable, well-built meter will work continuously at the extremes. Thousands of hours of operating life without drift or need for recalibration gives you a performance standard that you can rely on year after year. The Max line of gear flow meters meet this challenge.

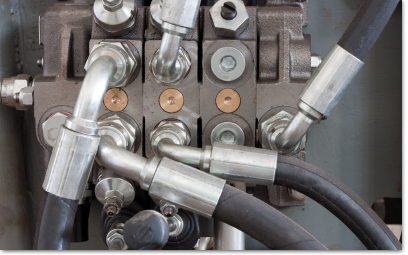

Max equipment specified:

The Max, G Series flow meters have a standard pressure rating of 414 bar (6000 psi) and the largest of the series, the Model G240 Gear Meter has a top flow rate of 240 LPM (63 GPM). The Max G Series of meters were developed to measure hydraulic oil flow rates with a low pressure drop. Their precision design handles the high flow rates without cavitation. Their tight internal clearances maintain +/- 0.3% accuracy over the meter’s 100:1 range. A full catalog of output signal choices is available to suit your data acquisition needs. If you would like a quote for a similar project, please let us know.