Fluorocarbons, such as Freon® and other HFC mixtures used as blowing agents in urethane foam share the characteristic of being low viscosity liquids. To accurately measure these fluids with a positive displacement meter requires both tight machining clearances within the meter and a minimum pressure differential to reduce internal blow by. Max Machinery’s line of piston flow meters achieves both of these requirements and is used extensively in the manufacturing of urethane foam.

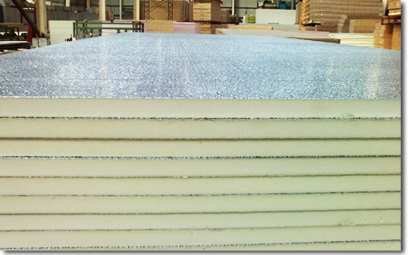

In the Urethane foam industry, blowing agents are used to create open cells within a urethane matrix. The density of the foam is based on a precise amount of blowing agent. This agent must be evenly distributed throughout the foam so as to provide a homogeneous final product. Lack of on-the-fly control or the inability to measure the amount of blowing agent that is being added to the mix will destroy hundreds of feet of foam and waste thousands of dollars in raw materials and production time. To prevent inconsistency in the final product, foam manufacturers use Max meters to measure and control their foaming process.

Max Equipment Specified: The Max P215 meter, with its 9000 pulses/pound resolution is the industry standard for tight ratio control over a wide flow range (0.15 to 70 lb/min). If you would like a quote for a similar project, please let us know.

Freon as a blowing agent in urethane foam

Flow meter accuracy, repeatability and low internal leakage for low viscosity blowing agents

Products Specified for this Application

25 cc/min to 35 liters/min (0.006 to 10 gpm) with a 210 bar (3000 psi) pressure rating